News & Events Back

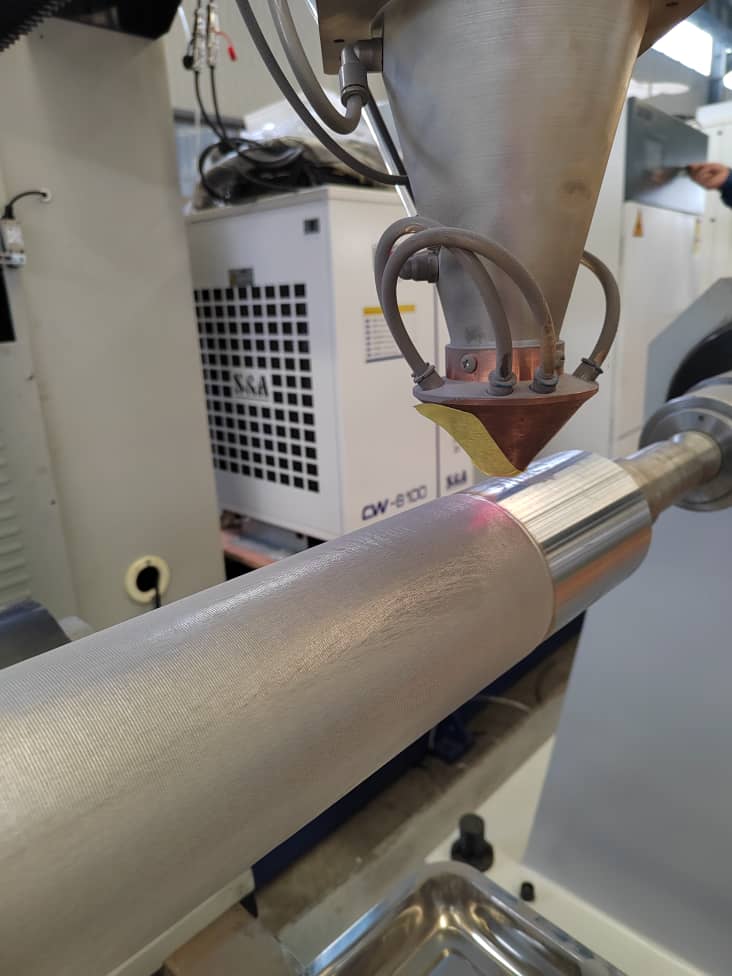

Ultra HighSpeed Low Tempurature Laser Cladding

With exactly 12 months of development work, today marks the launch of among the most significant milestones in WWG Engineering's technology roadmap. The official launch of WWG Engineering's Ultra HighSpeed Low Temperature Laser Cladding Process.

As the largest integrated one-stop engineering solutions facility in Singapore, UHLA is designed to offer as an alternative to hard chrome plating and to certain extend, HVOF coating. Plus, this will complement WWG's existing spectrum of surface engineering solutions, to further enhance completeness of its various surface coating deposition processes.

WWG Engineering's immediate focus is UHLA cladding of Shafts and Rods. This also marks the birth of the largest shaft/rod Laser Cladding capacity in the region, the machine capacity is Swing 1,600 MM X Length 12,000 MM. UHLA allows metallurgically, fusion bonded coating deposition with zero or minimal parts deformation.

WWG communities and its business network are super excited with this news. At the mean time, more engineering effort is on-going to develop next version of advanced UHLA systems for more complex and wider applications.