News & Events Back

It has always been WWG Engineering's objectives to continue assemble some of the most sought-after Surface Modification and Surface Engineering Technologies under one-roof. Under careful planing and execution, such strategy would enhance completeness and offering of a very uniquely structured "Total Integrated Complete One-Stop Engineering Services Solutions".

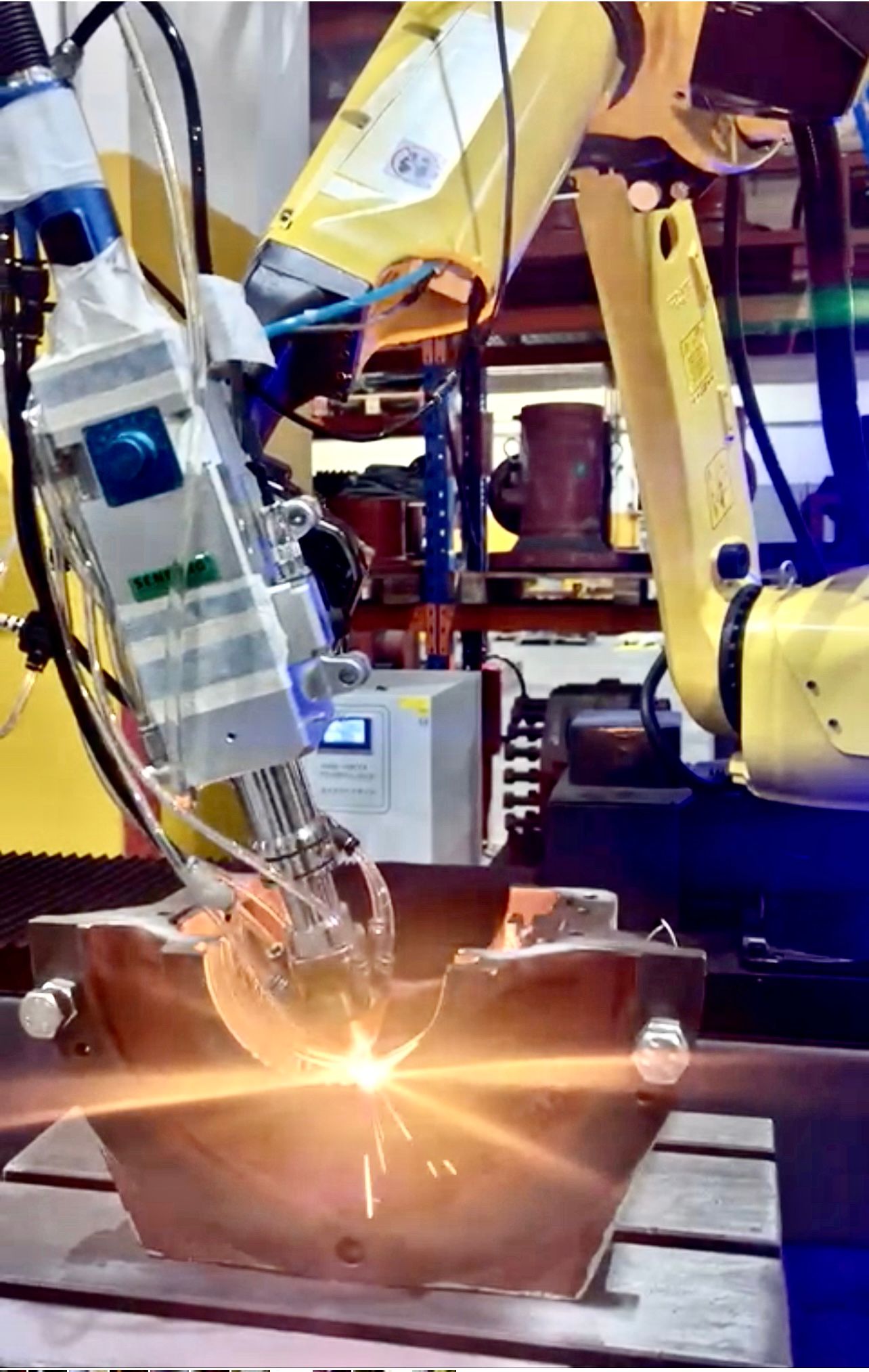

Since 2023, WWG Engineering has commitmitted approximately S$1 million into development of Ultra Highspeed Laser Applications. Starting with Laser Cleaning and Blasting, followed by a CNC automated Shaft Laser Cladding (Swing 1,600 mm X 12,000 mm X 15 tons), WWG Engineering Pte Ltd is announcing its successful installation and commissioning of a New Robotic UHLA Laser Cladding system (Swing 1,600 mm X Length 6,000 mm X 15 tons).

On top of usual cladding OD setup configuration, this new system would allow Laser Cladding of Inner Bore (Housing and Pipes ID), Narrow Gap (Piston Crown) and Deep Reach (example Crankshaft Journals).