Services Back

White Metal Bearings

In engineering applications, White Metal Bearings is primarily used to line cast iron, steel and bronze bearing shells. Usually, it is a tin based or lead based alloy containing moderate amounts of copper and antimony. In critical engineering environment such as Oil & Gas, Petrochemical and Power Generation industries in the high load and operating temperature applications, Tin based white metals are used.

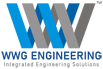

In the business of rebabbiting and remanufacturing of White Metal Bearing

White Metal Bearings

In engineering applications, White Metal Bearings is primarily used to line cast iron, steel and bronze bearing shells. Usually, it is a tin based or lead based alloy containing moderate amounts of copper and antimony. In critical engineering environment such as Oil & Gas, Petrochemical and Power Generation industries in the high load and operating temperature applications, Tin based white metals are used.

In the business of rebabbiting and remanufacturing of White Metal Bearings, experience and knowledge on bearing operating condition is vital. This is followed by precision machining, fit up of bearings, with knowledge of correct bearing shell or housing crush.

WWG Engineering Pte Ltd has been in the White Metal Bearing business over a decade. Main applications are:

- Turbine, Compressor, Pump shaft bearings

- I.D. Fan bearings

- Forced Draft (FD) bearings

- Circulation Water (CW) bearings

- Pump and Turbine thrust pads

- Motor thrust pads

- Thrust faces of special journal bearings

- Diesel Engine Block bearings

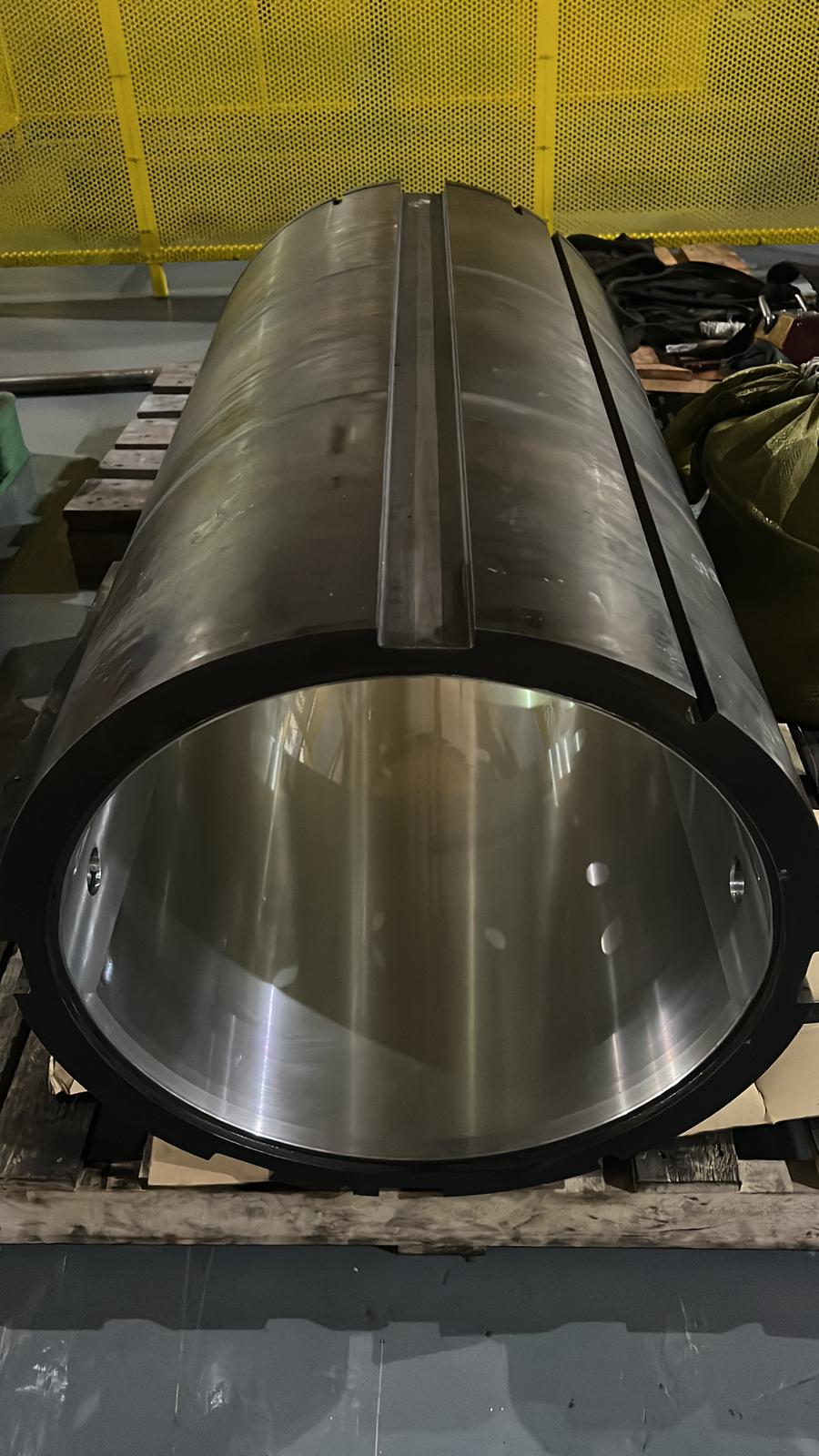

In recent years, WWG Engineering is among the very few to undertake remetalling work for Propeller Shafts' Very Large (near 2 m length) Stern Tube Bearings, FWD/AFT Stern Tube Bearings, Intermediate Bearings, Plummer Block Bearings etc. WWG Engineering has its experience to preform remetalling, complete machining, inclusive of offsetting and multi-slopes machining, within record timing.