Services Back

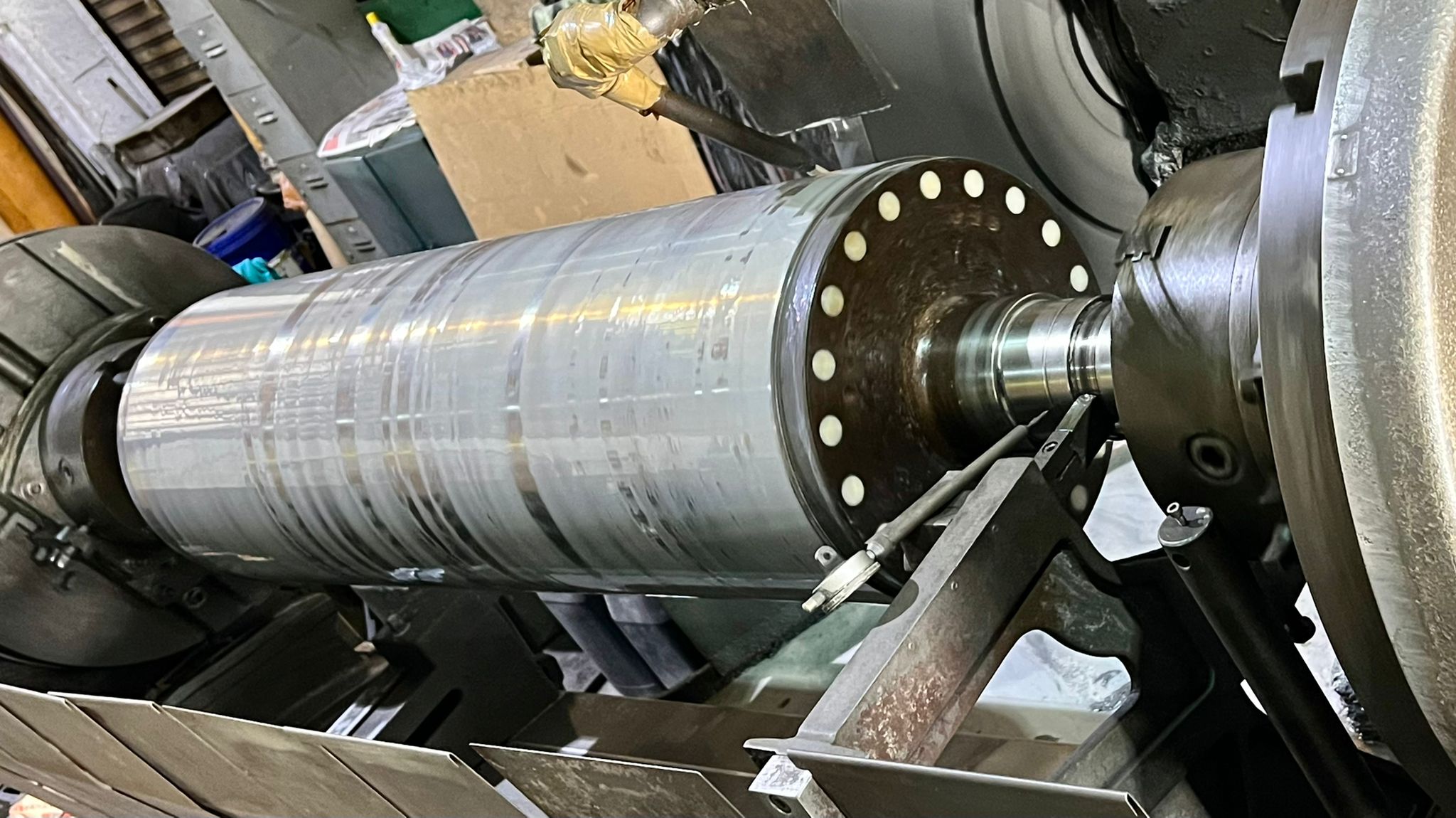

Hard Chrome Plating

WWG Engineering offer the hard chrome services, with facility and plating tanks capable of accepting components from small to large items.

Hard chrome plating is a very hard electroplating process in which chromium is deposited from a chromic acid solution. Thickness of hard chrome plating ranges 25 - 1,000 microns thickness for a wide range of applications. Electro-deposited Chrome is extremely hard, with typical values of 850 - 1050 HV (63 - 70 HRc), hence the term "Hard"

Hard Chrome Plating

WWG Engineering offer the hard chrome services, with facility and plating tanks capable of accepting components from small to large items.

Hard chrome plating is a very hard electroplating process in which chromium is deposited from a chromic acid solution. Thickness of hard chrome plating ranges 25 - 1,000 microns thickness for a wide range of applications. Electro-deposited Chrome is extremely hard, with typical values of 850 - 1050 HV (63 - 70 HRc), hence the term "Hard" Chrome.

The thinner deposits being used to substantially increase the life of components in wear applications or corrosive environments, and the thicker deposits being used for salvage and repair of worn, damaged or mis-machined components. Hard Chrome has low coefficient of friction and its self-lubricating properties hard chrome is an IDEAL material for any wear surface in any. The high hardness and low frictional properties of Hard Chrome provide it with extremely good resistance to abrasive and erosive wear. Hard Chrome has an extremely high resistance to atmospheric oxidation, and a good resistance to most oxidising and reducing agents.

Hard Chrome is classed as a "COLD" process; the operating temperature of 50 - 60°C ensures no detrimental effects to the physical or mechanical properties of the base materials. Hard Chrome can be deposited successfully and advantageously onto most metallic substrate materials.

Applications- Hydraulic and Pneumatic Piston Rods and Cylinders

- Moulds, Dies, Screws, etc.

- Print Cylinders and Plates

- Valves, Gates and Bodies

- Mining Equipment

- Pump Shafts and Rotors

- Textile Components